OAP(Off-Axis Parabolic) 미러 개론

OAP(Off-Axis Parabolic) 미러 개론

포물선 미러는 구면 수차를 발생시키지 않고 시준된 광원의 초점을 맞출 수 있습니다. OAP(Off-Axis Parabolic) 미러는 축상 포물선형 미러에 해당합니다(그림 1). 시준된 광원이 OAP 미러에 입사하면 한 지점에 초점이 맞춰집니다. 그림 2를 보면 OAP 미러는 중심 포물선형 미러와 달리 빔을 방해하지 않으면서 초점 주변에 더 많은 상호작용 공간을 확보할 수 있다는 장점이 있습니다.

그림 1: Gold 코팅 처리가 된 OAP(Off-Axis Parabolic) 미러

그림 2: 독특한 형태의 미러가 어떻게 초점을 맞추는지 보여주는 OAP(Off-Axis Parabolic) 구조

OAP 미러의 포물선 영역에서 구역을 어떻게 설정하는지에 따라 초점과 중심 광선 축 사이의 각도가 커지거나 작아질 수 있습니다. 이와 같은 현상을 보여주는 그림 3은 각각 15° 및 45°의 OAP 미러를 모델링한 것입니다. 참고: 각도 변위가 있으면 코마 수차가 발생하기 때문에 입사 빔을 광축과 평행하게 유지해야 합니다.

그림 3: 15° 및 45°의 OAP(Off-Axis Parabolic) 미러 구조

OAP(Off-Axis Parabolic) 미러 코팅

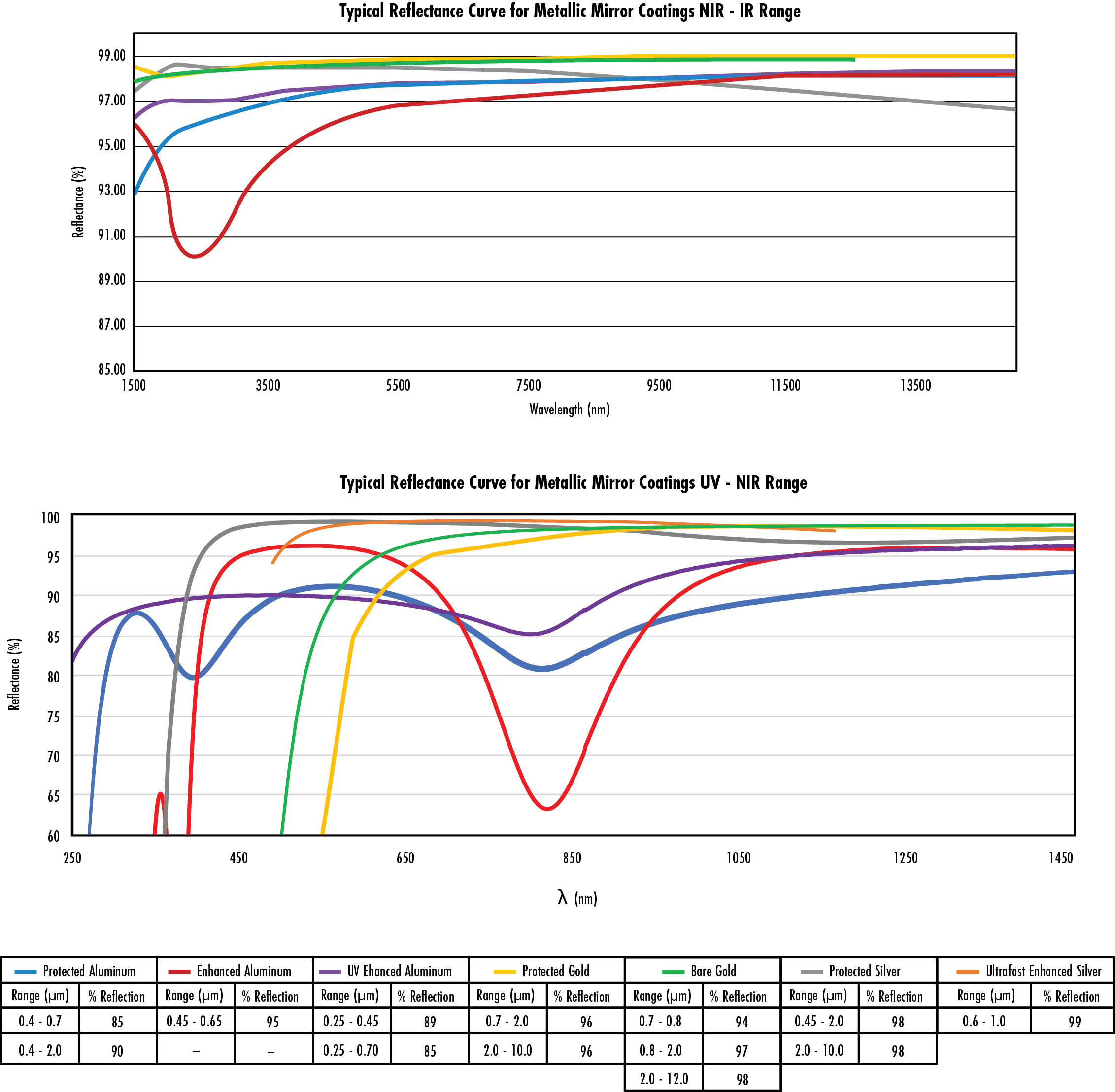

에드몬드옵틱스는 코팅 옵션이 다양한 OAP(Off-Axis Parabolic) 미러를 기성품으로 제공하며 즉시 배송이 가능합니다(그림 4). 맞춤형 설계 및 제조 역시 가능합니다.

그림 4: OAP(Off-Axis Parabolic) 미러 코팅 옵션별 반사율 곡선

표면 거칠기가 성능에 미치는 영향

표면 거칠기는 광학 표면에 나타나는 공간 주파수 오차가 높은 경우를 말합니다. 이는 표면에서 예기치 않게 다른 방향으로 산란되는 빛의 양에 영향을 줍니다(그림 5). 권장되는 표면 형상과의 편차를 측정하는 경우 보통 단위로 옹스트롬(Å)을 사용하며 에드몬드옵틱스의 OAP 미러는 RMS 표면 거칠기가 <50Å 혹은 <100Å입니다. 자세한 내용은 어플리케이션 노트 중 다이아몬드 선삭을 적용한 OAP(Off-Axis Parabolic) 미러의 거칠기를 참고하세요.

그림 5: 일반적인 산란 프로파일을 비교해 보면 표준형 OAP 미러(좌)는 산란되는 빛이 많이 발생하지만 동급의 TECHSPEC® 50Å OAP 미러(우)는 불필요한 산란이 감소함

OAP(Off-Axis Parabolic) 미러 선택 가이드

아래의 선택 가이드는 에드몬드옵틱스에서 제공하는 다양한 OAP(Off-Axis Parabolic) 미러 옵션 관련 정보를 자세히 설명하고 있습니다.

| TECHSPEC® OAP 미러 | |||||

|---|---|---|---|---|---|

| 코팅 옵션 | 오프셋 각도 옵션 | 표면 거칠기 옵션 | 얼라인먼트 스루홀 포함 여부 | 극초단 레이저 펄스 사용 가능 여부 | |

| 골드 OAP | Bare Gold, Protected Gold Ravg ≥94% @ 700 - 800nm Ravg ≥97% @ 800 - 2,000nm Ravg ≥98% @ 2,000 - 12,000nm |

15°, 30°, 45°, 60°, 90° | <50Å, <100Å | X | X |

| 알루미늄 OAP | Protected Aluminum Ravg ≥85% @ 400 - 700nm Ravg ≥97% @ 2,000 - 12,000nm Enhanced Aluminum Ravg >89% @ 250 - 450nm Ravg >85% @ 250 - 700nm |

15°, 30°, 45°, 60°, 90° | <50Å, <100Å | X | X |

| 실버 OAP | Protected Silver Ravg ≥98% @ 2,000 - 12,000nm |

90° | <100Å | X | X |

| 레이저 라인 OAP | 레이저 라인 코팅 Nd:YAG 설계 파장에서 반사율이 99.5% 이상 |

90° | <50Å | X | X |

| 극초단 강화 실버 OAP | Ultrafast-Enhanced Silver Ravg >99% @ 600 - 1000nm, 0° Rs >99% @ 540 - 1000nm, 45° Rp >98.5% @ ~730 - 870nm, 45° |

90° | <50Å | X | O, 600 - 1050nm 파장 대역에서 GDD(Group Delay Dispersion, 군지연분산)가 0±20fs2로 낮음 |

| 얼라인먼트 스루홀이 있는 OAP | Enhanced Aluminum, Protected Aluminum, Protected Gold | 90° | <50Å | O | X |

표 1: 에드몬드옵틱스에서 취급하는 기성품 OAP(Off-Axis Parabolic) 미러 비교

맞춤형 OAP(Off-Axis Parabolic) 제조 역량

에드몬드옵틱스의 엔지니어는 맞춤형 OAP(Off-Axis Parabolic) 미러와 비축 타원형 미러를 비롯한 여러 광학 부품을 설계하고 다이아몬드 선삭 가공을 수행합니다. 아래의 동영상을 통해 자체 다이아몬드 선삭에 대해 알아보세요. 더 자세한 정보를 원하시면 아래 링크를 클릭하세요. 견적 요청도 가능합니다.

Please accept marketing-cookies to watch this video.

본사 및 지사별 연락처 확인하기

견적 요청 도구

재고 번호 입력 필요

Copyright 2023, 에드몬드옵틱스코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동, 풍성빌딩)