Laser Damage Threshold 테스트

본 내용은 레이저 옵틱스 리소스 가이드의 단원 3.2, 3.3과 3.4에 해당합니다.

레이저 손상 테스트는 본래부터 파괴적인 측면을 가지고 있습니다. 손상 테스트를 받는 옵틱은 일정 수준의 레이저 세기에 노출된 후 Nomarski-type differential interference contrast (DIC) 현미경으로 검사가 진행됩니다. 그다음 레이저의 세기를 증가시키면서 노출과 검사 과정을 반복하게 됩니다. 이러한 절차는 옵틱에 손상이 관찰될 때까지 계속되며 개념적으로는 단순한 과정일 수 있으나 정도가 다른 몇 가지 복잡한 양상을 보입니다.

ISO 21254 규정에 따르면 테스트 중에 검출되는 옵틱 내의 변화는 "손상"으로 간주합니다. 모든 테스트가 동일한 손상 검출법을 사용하지 않고 운영자마다 선택한 signal-to-noise threshold가 다를 수 있어 손상을 평가하는 방식에 따라 각기 다른 LIDT 값이 생성될 수 있습니다. 따라서 ISO가 "손상"으로 규정짓는 것이 어플리케이션에 따라 다르기 때문에 꼭 성능 저하를 의미하는 것은 아니라는 점을 알고 있어야 합니다.

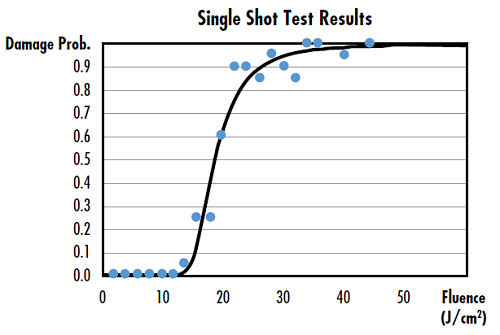

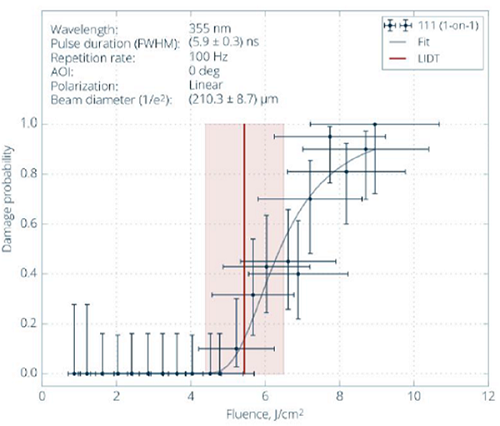

LIDT 테스트는 싱글 또는 멀티샷 테스트로 지정됩니다. 싱글샷 테스트(single-shot test)는 1-on-1 테스트로도 알려져 있으며 다양한 레이저 세기를 이용해 광학 부품 전체에 걸쳐 최소 10개의 각기 다른 샘플 부위에서 레이저 방사선을 단 한 번만 발사하는 방식입니다. 해당 레이저 세기에서 시험한 부위의 총 개수 중에서도 손상된 부위의 수가 특정 세기에서의 손상 확률을 결정합니다. 플루언스와의 함수 관계를 이용하면 손상 확률을 그래프로 도식화할 수 있으며 선형으로 제공되는 데이터를 근거로 손상이 0%인 지점을 찾게 되면 LIDT 값을 알아낼 수 있습니다(그림 1).

그림 1: 싱글 샷 테스트 후의 샘플 데이터

멀티샷 또는 S-on-1 테스트는 테스트할 사이트마다 싱글샷이 아닌 일련의 레이저 샷 또는 펄스를 사용한다는 점에서 싱글샷 테스트와는 다릅니다. 사이트당 혹은 S당 일반적인 샷의 수는 10에서 1000 사이입니다. 멀티샷 테스트는 옵틱의 실제 성능을 더 정확하게 예측해주고 LIDT 테스터가 infant mortality realm라고 불리는 현상을 피할 수 있도록 합니다.1 사이트당 1에서 10회 사이의 샷을 사용할 때 테스트 결과는 비결정론적이기 때문에 높은 수준의 통계학적 변화를 보입니다. 이때 사이트당 샷의 범위를 초기 파손율의 범위(infant mortality realm)라고 합니다. S가 10보다 클 경우에는 보다 결정론적이면서 예측 가능성이 높은 테스트 결과를 갖게 됩니다. 따라서 사이트당 대략 100개의 샷이 사용될 때 장기적인 성능을 예측할 수 있는 충분한 정보를 수집할 수 있습니다. 다만 사이트당 이 이상의 샷을 사용하면 LIDT 테스트 시간이 길어지고 더 많은 비용이 부담될 수 있습니다.

손상 감지 방법

테스트 결과는 손상 평가에 사용되는 감지 방법에 따라 상당히 달라질 수 있으며 현재로서는 손상 감지 방식에 대해 업계 간의 합의가 이루어지지 않은 상태입니다. 손상을 감별하는 데 가장 흔히 사용되는 방법은 현미경 검사법이지만 산란광 진단, 플라즈마 스파크 모니터링, 지형 분석 등의 몇 가지 다른 감지법도 있습니다.

DIC 현미경 검사법

Nomarski-type differential interference contrast (DIC) microscopy는 ISO 21254 규정을 준수하면서 레이저 손상 감지에 가장 흔히 사용되는 방법입니다. DIC 현미경 검사법은 간섭계를 이용하는 방식으로서 투명한 샘플의 이미지 콘트라스트를 향상시켜 식별하기 어려운 결점을 관찰할 수 있도록 합니다.2 일단 테스트 전후로 옵틱의 이미지가 촬영되면 인적 판단이나 이미지 처리 기법을 이용해 손상을 확인할 수 있습니다. 인적 판단으로 감별 시에는 조작자의 주관적인 판단이 개입될 수 있어 테스트 결과가 크게 달라질 수 있는 반면 이미지 처리 알고리즘은 인적 판단으로 인한 실수를 야기하지 않고도 손상을 감지할 수 있습니다. 다만 이미지 처리법의 경우에도 비네팅, 비균일 조도, 정렬 불량으로 인한 긍정 오류(false positive)가 발생할 수 있습니다. 이처럼 DIC 현미경 검사법을 활용하면 옵틱의 손상 여부 뿐만 아니라 결함의 치수까지 알아낼 수 있습니다.

산란광 진단법

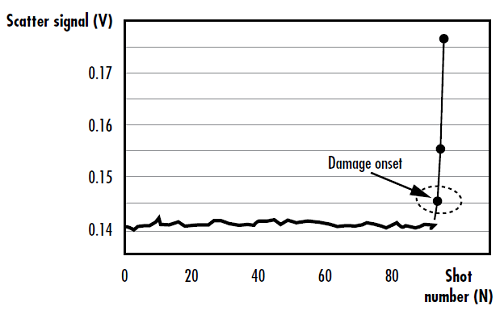

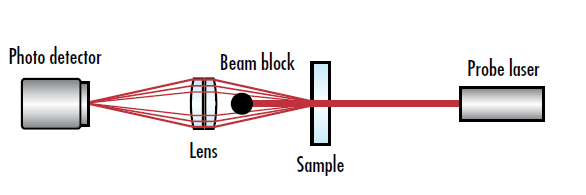

ISO 21254 규정에 따라 정의된 또 다른 감지 방법으로는 산란광 진단법(scattered light diagnostics)이 있습니다. 이 방법은 목표 지점에서 산란된 빛을 이용해 레이저 유도 손상의 여부와 특성을 확인하는 데 사용됩니다.2 산란광 진단법에서 프로브 빔(대체로 HeNe 레이저)은 목표 지점을 비추는 역할을 하며 백그라운드 노이즈보다 산란된 시그널의 차이가 더 크다는 것은 옵틱의 손상이 존재함을 의미합니다(그림 2). 프로브 빔 자체는 디텍터에 도달하기 전에 차단되어 손상 부위에서는 산란된 빛만 검출됩니다.

그림 2: 레이저 유도 손상이 발생한 후 산란 시그널의 급격한 변화

산란광 진단법은 디텍터의 입체각(solid angle)이 클수록 측정에 더 민감하다는 표준 구성을 따릅니다. 이 진단법은 백그라운드 노이즈 양에 따라 측정값이 크게 좌우된다는 단점을 가지고 있습니다. 이와 같은 의존성를 해결하려면 여러 번의 측정으로 도출된 결과를 평균화하거나 디텍터의 gain을 증가시켜야 하며 또는 백그라운드 노이즈를 걸러내야 합니다.

그림 3: LIDT 테스트를 위해 산란광 검사에 필요한 대표적인 구성 방식

플라즈마 스파크 모니터링

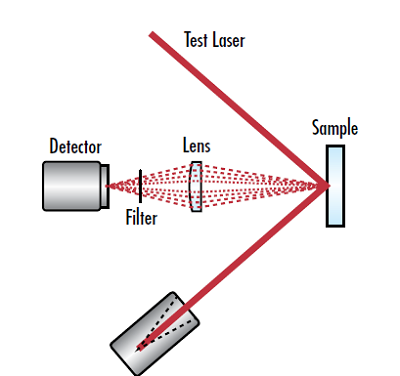

플라즈마 스파크 모니터링(plasma spark monitoring)은 레이저로 인한 손상을 감지하는 데 사용되는 또 다른 기법 중 하나입니다. 레이저 유도 손상이 발생하면 종종 비공진 광학적 고장(소위 플라즈마 스파크)으로 인해 광학 표면에 플라즈마가 생성되면서 손상 부위 주변에 플라즈마 열상(plasma scald)이 형성되는 결과를 낳게 됩니다. 플라즈마 스파크나 열상이 발견된다는 것 자체가 광학적 손상이 존재한다는 뚜렷한 징후입니다.2 플라즈마 열상은 상대적으로 고른 표면을 가지고 있어 현미경 검사나 산란광 진단을 통해 발견하기가 상당히 어렵습니다. 하지만 플라즈마 스파크에서 방출되는 빛을 디텍터에 집중시키는 집광 렌즈를 이용해 LIDT 테스트를 하면 플라즈마 스파크를 검출할 수 있습니다(그림 4). LIDT 감지하기 위해서는 테스트 레이저로부터 산란되는 빛을 걸러내야 하고 일반적으로 최대 100ns으로 발생하는 플라즈마 스파크의 지속 시간보다 디텍터의 응답 시간이 짧아야 합니다.

그림 4: LIDT 테스트를 위해 플라즈마 스파크 모니터링에 필요한 대표적인 구성 방식

표면형상 분석

레이저로 인한 손상부의 표면형상 분석(topography analysis)에는 손상의 크기와 깊이에 관한 특성을 규정짓는 레이저 유도 손상 부위의 높이 지도(height map) 생성이 포함됩니다.2 이 방식은 다른 감지법보다 시간이 더 많이 소요되는 경향이 있어 일반적으로는 잘 사용되지는 않습니다. 다만 손상을 유도하는 기본 메커니즘을 파악하는 데 필요한 유용한 정보가 이 방법을 통해 제공됩니다. 표면형상 분석은 광학 현미경, 원자간력 현미경(AFM), 전자 현미경 스캐닝(SEM), 스텝 프로파일러, 백색광 간섭측정(WLI) 등 여러 가지 기법으로 수행될 수 있습니다.

각기 다른 유형의 레이저 유도 손상을 감지하기 위해서는 다양한 기술이 동원되어야 합니다. 스텝 프로파일러와 원자간력 현미경은 깊이가 낮은 손상 부위(1 나노미터 깊이에 대략 200µm의 직경)를 정밀 측정하는 데 적합합니다. 두 가지 기법 다 프로브 기계를 이용해 샘플을 스캔하고 프로브의 편향(deflection)을 기반으로 한 높이 지도를 생성합니다. 원자간력 현미경 시스템은 가시광의 광학적 회절 제한보다 1000배 이상 작은 대략 수 나노미터의 분해능을 달성할 수 있습니다.

전자 현미경 스캐닝은 다중 코팅 증착 과정에서 남겨진 패인 자국(pit)을 포함해 종횡비(너비 대 깊이의 비율)가 약 1인 더 깊은 손상 부위를 측정할 때 스텝 프로파일러와 원자간력 현미경 검사보다 더 효과적인 방식입니다. 전자 현미경 스캐닝은 광자보다 훨씬 더 깊숙이 침투할 수 있는 전자로 구성된 집속 빔(focused beam)을 이용해 샘플의 표면을 스캐닝하고 이미지를 생성합니다.3 스텝 프로파일러와 원자간력 현미경은 슬로프가 가파르기 때문에 접촉 프로브로 결함의 바닥면까지 도달해 정확한 측정값을 산출하는 데 어려움이 있어 손상이 깊은 부위를 측정하기에는 부적합니다.

기존의 표면형상 분석 기법은 옵틱의 표면만 검사하기 때문에 벌크 소재나 핀포인트 구조 내부로 매우 깊이 침투하는 손상 부위는 측정에 있어 더 많은 어려움이 따릅니다. 이처럼 깊은 손상을 측정하기 위해서는 앞서 언급한 방식 중 하나를 활용해 다양한 깊이에서 횡단면을 측정할 수 있도록 절삭(cleaving)이나 식각(etching)으로 벌크 소재를 노출시켜야 합니다. 그런 다음 횡단면을 완전한 3D 지형도로 결합할 수 있습니다.

LIDT 테스트 결과 해석하기

광학 부품에 지정되는 LIDT는 손상 가능성이 제로일 때의 레이저 플루언스를 알려주는 테스트 데이터를 선형 추론하여 결정됩니다. 그러나 이는 실제로 선형이 아닌 데이터에 딱 맞는 직선형을 나타냅니다. LIDT라는 단일 수치가 모든 필수 정보를 제공하는 것은 아니며 지정된 LIDT 이하에서는 여전히 손상 가능성이 존재합니다. Weibull 및 Burr 분포도는 LIDT 데이터에 훨씬 더 정확한 적합성를 제공하는 연속 확률 분포를 나타냅니다(그림 5).

그림 5: LIDT 값(적색 수직선)과 최적의 2-parameter Weibull 분포로 테스트한 실제 LIDT 데이터. 지정된 LIDT 값보다 낮을 경우에는 여전히 손상 가능성이 존재함

5 J/cm2 정도의 플루언스에서는 LIDT가 지정된 값보다 낮을 경우에도 손상 가능성이 존재합니다. 손상 확률의 수직 에러 바(vertical error bar)는 테스트 부위의 개수에 의해 발생하고 수평 플루언스의 에러 바(horizontal error bar)는 테스트 레이저의 레이저 샷 변동에 의해 발생합니다. 레이저 제품이 완벽하지 않은 이상 일정 수준의 핫스폿이나 강도 변화는 항상 존재하기 마련입니다. 이를 해결하기 위해서는 레이저의 사용 조건보다 더 높은 수준의 LIDT를 가지고 있는 옵틱을 선정하고 반드시 안전 계수를 추가해야 합니다. 이때 필요한 안전 계수는 어플리케이션과 레이저 유형에 따라 달라지기 때문에 모든 상황에 적합한 범용 안전 계수는 존재하지 않습니다. 광학 업계에서는 일반적으로 세 개에서 두 개 정도의 안전 계수를 이용합니다. 다만 레이저로 유도되는 손상이 결함에 의해 일어난다면 서로 다른 안전 계수에서의 손상 확률을 평가하기 위해 통계학적 모델을 활용할 수도 있습니다(당사 어플리케이션 노트 Laser Damage Threshold에 관한 빔 직경의 중요성 참조).

참고 문헌

- Johnson, Lawrence A. Laser Diode Burn-In and Reliability Testing. ILX Lightwave, 2006.

- Ristau, Detlev. Laser-Induced Damage in Optical Materials. CRC Press, 2016.

- Kanaya, K. “Penetration and Energy-Loss Theory of Electrons in Solid Targets.” J. Phys. D: Appl. Phys. 5, 43, 1972.

이전 단원

이전 단원

본사 및 지사별 연락처 확인하기

견적 요청 도구

재고 번호 입력 필요

Copyright 2023, 에드몬드옵틱스코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동, 풍성빌딩)