LIDT 상에서 빔 직경의 중요성

본 내용은 레이저 옵틱스 리소스 가이드의 단원 3.5에 해당합니다.

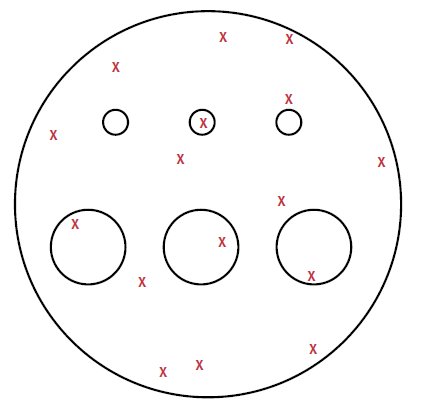

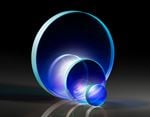

빔의 직경은 레이저 유도 손상 확률에 직접적인 영향을 미치기 때문에 광학 부품의 LIDT는 레이저 직경에 의해 좌우됩니다.1 LIDT 테스트에 사용되는 레이저 빔의 크기가 옵틱의 결함 밀도보다 현저하게 클 경우 희소 손상 메커니즘을 유발할 가능성이 높습니다. 단, 이처럼 발생 가능성이 희박한 경우라도 검출은 가능합니다. 빔의 크기가 지나치게 작다면 밀도가 낮은 결함은 항시 검출이 불가능하며 광학 부품이 실제보다 손상에 더 강한 내성을 가지고 있는 것처럼 나타납니다(그림 1).

그림 1: 직경이 작은 빔은 테스트를 받을 옵틱의 저밀도 결함과 중복될 가능성이 낮기 때문에 지나치게 낙관적인 LIDT 값이 산출됨

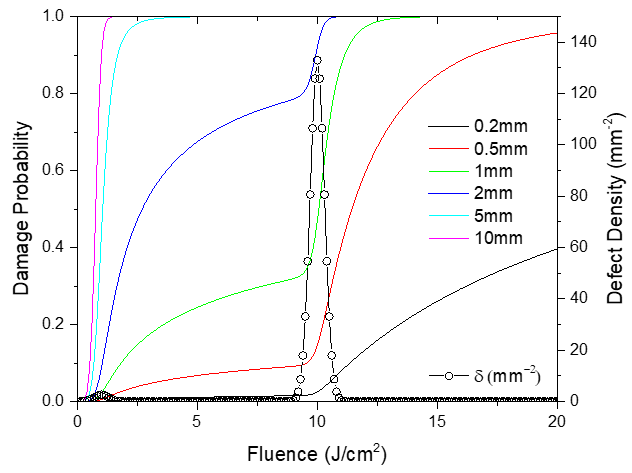

ISO 21254에서 규정에 따라 LIDT 테스트에 허용되는 빔의 최소 직경은 0.2mm입니다. 빔의 직경이 작을 경우 표면에 대한 “under-sampling”을 유발할 수 있지만 높은 플루언스를 얻기 쉽도록 다수의 레이저 광학 공급 업체는 가능한 크기가 작은 빔의 사용을 선호합니다. 그림 2은 레이저 손상이 빔의 직경에 따라 어떻게 증가하는지를 보여줍니다. 이 그림에서는 결함의 수가 많을 경우 threshold fluence는 10J이고 결함의 수가 적을 경우 threshold fluence는 1J이라는 시나리오를 확인할 수 있습니다. 레이저 광학 부품은 일반적으로 다양한 밀도와 각기 다른 damage threshold에 따라 여러 유형의 결함을 가지고 있기 때문에 이처럼 단순화된 모델을 통해 실제 사용에 관하여 통찰해볼 수 있습니다. 빔의 직경이 0.2mm에서 10mm로 증가하면 손상 확률 함수가 크게 변화하여 테스트를 통해 결정된 LIDT의 값이 변경될 수 있습니다. 0.2mm 빔의 경우 threshold가 1J인 결함들 중 하나를 발견할 가능성은 작습니다. 이러한 이유로 플루언스가 10J에 도달할 때까지는 손상 확률이 매우 낮게 유지됩니다. 빔의 크기를 0.2mm에서 2mm로 증가하면 threshold가 1J인 결함을 감지할 가능성이 더욱 높아져 플루언스가 1J일 때 손상 확률이 급격히 증가하게 됩니다. 빔의 직경을 10mm로 확대하면 1J에서의 손상 가능성은 거의 일정한 손상 확률로 증가합니다.

그림 2: 두 가지 유형의 결함을 가지고 있는 이 예제에서 빔의 크기가 0.2mm에서 10mm로 증가할 때 LIDT는 10배 감소함

LIDT가 파장과 펄스 지속시간의 변화에 따라 변경되는 동안 빔의 직경에 따라서도 변경이 일어납니다. 빔의 직경 변화가 작다면 변경된 LIDT는 원래 LIDT 값에 새 직경에 대한 원래 직경의 비율을 제곱한 값을 곱하여 근사치로 계산할 수 있습니다.1

참고 문헌

- L. Gallais, J. Capoulade, J.-Y. Natoli and M. Commandré, "Investigation of nanodefect properties in optical coatings by coupling measured and simulated laser damage statistics," J. Appl. Phys, vol. 104, p. 053120, 2008.

이전 단원

이전 단원

혹은 지사별 연락처 확인

견적 도구

재고번호 입력 후 바로 시작

Copyright 2023, 에드몬드 옵틱스 코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동 풍성빌딩)