Liquid Lens Features, Applications, and Technology

Liquid Lens Features

This is Section 7.2 of the Imaging Resource Guide.

Liquid lenses quickly adjust focus to accommodate objects located at various working distances (WDs). Liquid lenses are small, mechanically or electrically controlled cells containing optical-grade liquid. When a current or voltage is applied to a liquid lens cell, the shape of the cell changes. This change occurs within milliseconds and causes the optical power, and therefore focal length and WD, to shift. Many manufacturers have designed liquid lenses that operate via slightly different processes: electrowetting, current-driven polymer, or sound piezoelectric. Liquid lenses are an ideal solution for imaging applications requiring rapid focusing, high throughput, and depth of field (DOF) and WD accommodation.

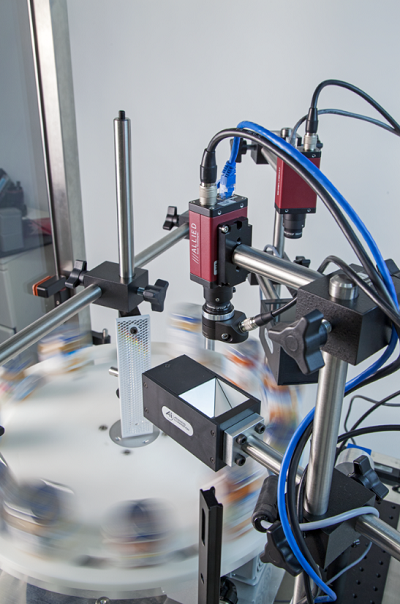

Figure 1: A liquid lens setup used in a high-speed machine vision application.

Response Time

Liquid lenses have very fast response times, are electrically tunable via voltage or current, and respond in a matter of milliseconds. Fixed Focal Length and Zoom lenses often rely on mechanical or manual adjustments to change focus, which can slow the imaging system.

Versatility

Liquid lenses can be implemented in various locations throughout an imaging system, such as being embedded within or threaded to the front or rear of an imaging lens.

Size

Mechanics are eliminated in a liquid lens which enables their compact design. In addition, liquid lenses are comparable in functionality to many individual lenses within an assembly. By removing those lenses and replacing them with a small liquid cell, the overall size and weight of the full lens is reduced.

Sensor Coverage

Liquid lenses are limited by their small aperture sizes - the largest is approximately 16mm in diameter. The small apertures restrict liquid lenses and only allow for use with sensors up to about 1/1.8” if the lens is retrofitted onto the front of an existing machine vision lens. Liquid lenses embedded inside systems do not reduce sensor coverage.

Focusing

Liquid lenses are designed to operate across a very wide range of optical powers (focal lengths) at high speeds. By eliminating the moving parts and mechanical adjustments typically found in fixed focal length and zoom lenses, the focusing process is quicker.

Complexity of Integration

Depending on available equipment and the application, liquid lenses can be difficult to integrate. Liquid lenses can be used in conjunction with many accessories, such as filters and apertures, which are required by many high-speed applications, such as distance sensors or controllers.

Lifetime

Liquid lenses consume very little power. Typical mechanical lenses are capable of ~100,000 cycles, whereas a liquid lens can withstand approximately ~50,000,000 cycles (Berge, 2013).

Liquid Lens Applications

This is Section 7.3 of the Imaging Resource Guide.

The adaptability, speed, and versatility of liquid lenses make them ideal for a variety of machine vision, life science, and measuring and inspection applications. Due to their traditional mechanical layout, standard machine vision lenses struggle to capture sharp and accurate images in high-speed or precise applications that require quick refocusing.

Machine Vision

High-volume assembly lines require fast, accurate, and precise throughput. Integrating a liquid lens into an inspection system is an optimal, compact, and economical solution when focusing at multiple distances is required. Liquid lenses are an ideal solution for barcode inspection, package sorting, quality control, and rapid automation.

Figure 2: This animation illustrates the advantages of implementing a liquid lens into a machine vision imaging system for inspection. In a standard inspection system, objects of different heights are imaged as they pass by on a fast-moving conveyor belt. A standard imaging lens requires mechanical refocusing per every object, causing a delay that can limit high-throughput. A liquid lens, free of mechanical translation, overcomes these speed and depth of field limitations by refocusing to different heights in the matter of milliseconds.

Life Sciences

Liquid lenses improve and simplify the process of focus stacking (“z-stacking”) in microscopy imaging applications. Focus stacking is often required when imaging with high magnification objectives due to their limited depths of field. A liquid lens can quickly and precisely focus to various object planes, therefore speeding up focus stacking. Liquid lenses can be easily integrated into tube lenses or in infinity

space within a microscope. Liquid lenses are often used in ophthalmology, where refraction control and depth of field adjustment is crucial. Standard ophthalmic equipment contains multiple glass lenses used to adjust for the human eye. These lenses can be replaced with a single liquid lens, speeding up the imaging or diagnosis process and decreasing the overall size of ophthalmic equipment such as OCTs and phoropters.

Unmanned Aerial Vehicles

By adding a liquid lens to an unmanned aerial vehicle (UAV) imaging system, image sharpness is quickly maintained across various heights. Liquid lenses are especially advantageous in agricultural inspection and monitoring, geographic information systems, and in surveillance applications.

Measurement and Dimensional Rendering

When paired with a distance sensor and camera, a liquid lens can quickly image different planes of a 3D object. The images are then stitched together in software to create an accurate three-dimensional rendering.

Liquid Lens Technology

This is Section 7.4 of the Imaging Resource Guide.

Corning® Varioptic® Variable Focus Liquid Lens Technology

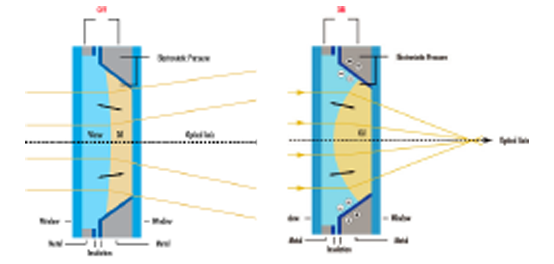

Variable Focus Liquid Lenses focus using a process called electrowetting, which is the application of electric fields to manipulate the wetting properties, and therefore shape and curvature, of a liquid. The liquid lens cell contains two immiscible liquids: a non-conductive oil and a water solution separated by an interface as shown in Figure 3. Applying a voltage at the interface between the two liquids changes the curvature, and therefore focal length, of the lens within tens of milliseconds. Applying more voltage increases the overall curvature and optical power of the liquid lens. The Variable Focus liquid lenses’ capacitive characteristics allows for stable operation in high-temperature environments once a thermal equilibrium is achieved. In addition, the two liquids within the lens have the same density, making the system insensitive to vibration and shock. Variable focus liquid lenses can be diff cult to work with, as their small size makes them challenging to use with existing objectives. They are better suited to be fully integrated into optical designs, where their size is less of a limiting factor.

Figure 3: Diagram illustrating the working principle of the Corning® Varioptic® Liquid Lens.

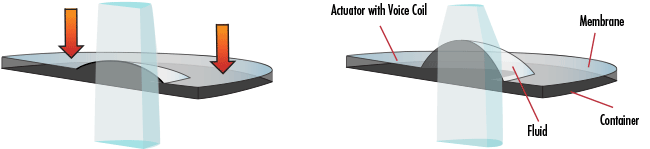

Optotune Electrically Focus-Tunable Lenses

Optotune Electrically Focus-Tunable Lenses consist of an optical fluid filled container sealed with a polymer membrane. A current-driven actuator exerts pressure on the membrane, causing the curvature of the lens (and therefore the optical power) to change. Due to their current dependency, electrically-focused tunable lenses function with low operating voltages and focus within milliseconds. These lenses do not alter polarization, have high laser damage threshold, and introduce minimal aberrations.

Previous Section

Previous Section

혹은 지사별 연락처 확인

견적 도구

재고번호 입력 후 바로 시작

Copyright 2023, 에드몬드 옵틱스 코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동 풍성빌딩)